The structure of brake pad

[Catalog:News] [Date:2020-9-4] [Hits:] [Return]

In the car brake system, brake pad is the most critical safety part, all the brake effect is the brake pad plays a decisive role, so a good brake pad is the protection of people and cars.

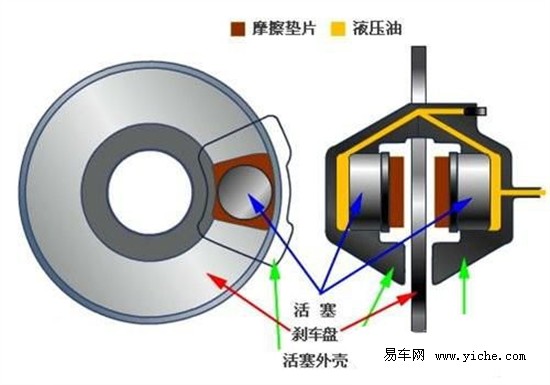

Brake pads are generally composed of steel plates, adhesive insulation layer and friction blocks. The steel plates should be coated to prevent rust. Smt-4 furnace temperature tracker is used to detect the temperature distribution during the coating process to ensure the quality.Heat insulation layer is composed of non-heat transfer materials, the purpose is to heat insulation.The friction block is composed of friction material and adhesive. When braking, it is squeezed on the brake disc or brake drum to produce friction, thus achieving the purpose of vehicle deceleration and braking.As a result of friction, friction blocks will be gradually worn, generally speaking, the lower the cost of the brake pads wear faster.After the use of friction materials to replace the brake pad in a timely manner, otherwise the steel plate will be in direct contact with the brake disc, and will eventually lose the brake effect and damage the brake disc.

Car brake pads are divided from the type

- Brake pads for disc brakes

- Brake shoes for drum brakes

- Reamer for large trucks

In terms of accessories, there are: semi-metal, less metal, asbestos, ceramic,

Brake drum is installed brake shoes, but the general people called brake shoes refers to the brake shoes and brake shoes, so with the "disc brake" to specifically specify the disc brake shoes.It's not a brake disc.

Formulation technology classification

From the formula technology is divided into: semi-metal, less metal, asbestos, ceramic, brake drum is installed brake shoes, but the general people called brake shoes refers to brake shoes and brake shoes, so "disc brake shoes" to specifically specify the disc brake shoes.It's not a brake disc.

The brake principle

The working principle of the brake is mainly from friction, which USES the friction between the brake pad, brake disc (drum) and tires and the ground to convert the kinetic energy of the vehicle moving into the heat energy after friction to stop the vehicle.A good and efficient braking system must provide stable, sufficient and controllable braking force and have good hydraulic transmission and cooling capacity to ensure that the driver's force from the brake pedal can be fully and effectively transmitted to the main pump and the sub-pump, and to avoid high heat caused by hydraulic failure and brake decline.There are two types of brake systems on cars, disc and drum, but despite the cost advantage, drum brakes are far less efficient than disc brakes, so the brakes in question will be disc brakes only.

Maintenance and inspection Methods Maintenance methods

Brake shoes, commonly known as brake shoes, are consumables that will gradually wear out in use. When the wear reaches the limit position, it must be replaced, otherwise it will reduce the effect of braking and even cause safety accidents.Brake shoe relates to life safety and must be treated with caution.

2. Brake shoes are generally composed of iron lining plate and friction material. Do not wait for friction material parts to be worn out before replacing shoes.For example, the front brake shoe of Jetta car, the thickness of the new film is 14 mm, and the limit thickness of the replacement is 7 mm, including the thickness of more than 3 mm iron lining plate and nearly 4 mm friction material thickness.Some vehicles with brake shoe alarm function, once reached the wear limit, the instrument will alarm prompt replacement shoe.Reached the limit of the shoe must be replaced, even if it can be used for a period of time, it will reduce the effect of braking, affecting the safety of driving.

3. When replacing, the brake pads provided by the original spare parts shall be replaced. Only in this way can the brake effect between the brake pads and the brake disc be the best and wear the least.

4. Special tools must be used to push back the brake pump when replacing the shoe.Do not use other crowbars to press back, this will easily lead to the brake clamp guide screw bending, the brake block stuck.

5. After the replacement, be sure to step on the brakes for a few feet to eliminate the gap between the shoe and the brake disc, resulting in no brake on the first foot, prone to accidents.

6. After the replacement of brake shoes, the best braking effect can be achieved only by running in 200 kilometers. The newly changed shoes should be driven carefully

Check the method

1. Look at the thickness.The thickness of the new brake pad is generally around 1.5cm. When the thickness of the brake pad is only about 0.5cm, the owner will be ready to replace it.

Listen to the sound.If there is a sound of "iron rubbing against iron" when the brakes are tapped, the brake pads must be replaced immediately.

3. Sensory strength.If you need to push the brake pedal deeper, check if the brake pads need to be replaced.

Matters needing attention

Brake drum is installed brake shoes, but the general people called brake shoes refers to the brake shoes and brake shoes, so with the "disc brake" to specifically specify the disc brake shoes.It's not a brake disc.

Brake pads are the most important safety parts in the brake system of a car.Because the brake effect is good or bad brake pad plays a decisive role, so said good brake pad is the guardian of people and cars.After the use of friction materials to replace the brake pad in a timely manner, otherwise the steel plate will be in direct contact with the brake disc, and will eventually lose the brake effect and damage the brake disc.

Brake pads are also called brake pads.In the car brake system, brake pad is the most critical safety part, all the brake effect is the brake pad plays a decisive role, so a good brake pad is the protection of people and cars.

The structure

Brake pads are generally composed of steel plates, adhesive insulation layer and friction blocks. The steel plates should be coated to prevent rust. Smt-4 furnace temperature tracker is used to detect the temperature distribution during the coating process to ensure the quality.Heat insulation layer is composed of non-heat transfer materials, the purpose is to heat insulation.The friction block is composed of friction material and adhesive. When braking, it is squeezed on the brake disc or brake drum to produce friction, thus achieving the purpose of vehicle deceleration and braking.As a result of friction, friction blocks will be gradually worn, generally speaking, the lower the cost of the brake pads wear faster.After the use of friction materials to replace the brake pad in a timely manner, otherwise the steel plate will be in direct contact with the brake disc, and will eventually lose the brake effect and damage the brake disc.

Car brake pads are divided from the type

- Brake pads for disc brakes

- Brake shoes for drum brakes

- Reamer for large trucks

In terms of accessories, there are: semi-metal, less metal, asbestos, ceramic,

Brake drum is installed brake shoes, but the general people called brake shoes refers to the brake shoes and brake shoes, so with the "disc brake" to specifically specify the disc brake shoes.It's not a brake disc.

Formulation technology classification

From the formula technology is divided into: semi-metal, less metal, asbestos, ceramic, brake drum is installed brake shoes, but the general people called brake shoes refers to brake shoes and brake shoes, so "disc brake shoes" to specifically specify the disc brake shoes.It's not a brake disc.

The brake principle

The working principle of the brake is mainly from friction, which USES the friction between the brake pad, brake disc (drum) and tires and the ground to convert the kinetic energy of the vehicle moving into the heat energy after friction to stop the vehicle.A good and efficient braking system must provide stable, sufficient and controllable braking force and have good hydraulic transmission and cooling capacity to ensure that the driver's force from the brake pedal can be fully and effectively transmitted to the main pump and the sub-pump, and to avoid high heat caused by hydraulic failure and brake decline.There are two types of brake systems on cars, disc and drum, but despite the cost advantage, drum brakes are far less efficient than disc brakes, so the brakes in question will be disc brakes only.

Maintenance and inspection Methods Maintenance methods

Brake shoes, commonly known as brake shoes, are consumables that will gradually wear out in use. When the wear reaches the limit position, it must be replaced, otherwise it will reduce the effect of braking and even cause safety accidents.Brake shoe relates to life safety and must be treated with caution.

1. Check the brake shoes every 5000 km under normal driving conditions. Check not only the remaining thickness, but also the wear state of the shoes.

2. Brake shoes are generally composed of iron lining plate and friction material. Do not wait for friction material parts to be worn out before replacing shoes.For example, the front brake shoe of Jetta car, the thickness of the new film is 14 mm, and the limit thickness of the replacement is 7 mm, including the thickness of more than 3 mm iron lining plate and nearly 4 mm friction material thickness.Some vehicles with brake shoe alarm function, once reached the wear limit, the instrument will alarm prompt replacement shoe.Reached the limit of the shoe must be replaced, even if it can be used for a period of time, it will reduce the effect of braking, affecting the safety of driving.

3. When replacing, the brake pads provided by the original spare parts shall be replaced. Only in this way can the brake effect between the brake pads and the brake disc be the best and wear the least.

4. Special tools must be used to push back the brake pump when replacing the shoe.Do not use other crowbars to press back, this will easily lead to the brake clamp guide screw bending, the brake block stuck.

5. After the replacement, be sure to step on the brakes for a few feet to eliminate the gap between the shoe and the brake disc, resulting in no brake on the first foot, prone to accidents.

6. After the replacement of brake shoes, the best braking effect can be achieved only by running in 200 kilometers. The newly changed shoes should be driven carefully

Check the method

1. Look at the thickness.The thickness of the new brake pad is generally around 1.5cm. When the thickness of the brake pad is only about 0.5cm, the owner will be ready to replace it.

Listen to the sound.If there is a sound of "iron rubbing against iron" when the brakes are tapped, the brake pads must be replaced immediately.

3. Sensory strength.If you need to push the brake pedal deeper, check if the brake pads need to be replaced.

Matters needing attention

Brake drum is installed brake shoes, but the general people called brake shoes refers to the brake shoes and brake shoes, so with the "disc brake" to specifically specify the disc brake shoes.It's not a brake disc.

Brake pads are the most important safety parts in the brake system of a car.Because the brake effect is good or bad brake pad plays a decisive role, so said good brake pad is the guardian of people and cars.After the use of friction materials to replace the brake pad in a timely manner, otherwise the steel plate will be in direct contact with the brake disc, and will eventually lose the brake effect and damage the brake disc.